Certania

Industrial Analytics

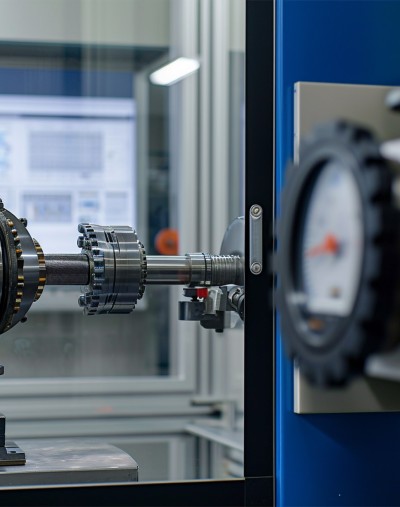

Our INDUSTRIAL ANALYTICS segment combines a broad and in-depth portfolio of testing, analysis and calibration methods that are essential for the quality assurance of modern industrial products. These include destructive and non-destructive testing methods, mechanical tests, metallography, fracture assessments and damage analyses, supplemented by high-precision optical and spectrometric methods for element and material characterisation.

One focus is on aerosol and filter analysis: From the smallest laboratory filters to cabin and room air systems to turbine filters, particle separation performance and adsorption capacities are tested. The range of services also includes the provision of specialised test media and standard dusts.

Calibration is another central pillar: Devices and measuring systems for ultrasound, radiometry, hardness or magnetometry are precisely calibrated, maintained and repaired. This ensures regulatory conformity – including quality assurance, inspection and technical documentation.

In addition, modern laboratories enable sample production, precision mechanics and complete test chains from a single source. Industries such as automotive, aviation, energy, mechanical engineering, medical technology, agricultural technology and the cleanroom industry benefit from in-depth technical expertise, high reproducibility and fast turnaround times.

INDUSTRIAL ANALYTICS thus creates a reliable basis for product quality, safety, material integrity and the optimisation of industrial processes.

For a humanity in certainty

IndustrialAnalytics

As a leading calibration laboratory that adheres to the highest standards, we offer one of the most comprehensive accredited ranges of services in the field of non-destructive testing. From ultrasonic, radiometric and photometric calibrations to magnetometry and hardness measurements, we ensure that measuring devices are precise and compliant across all industries. We also take on the maintenance, inspection and repair of testing and measuring systems and provide support with technical equipment sales and specialized training programs. Our work meets the highest quality standards and strengthens our customers' industrial performance in the long term.

CERTANIA INDUSTRIAL ANALYTICS stands for independent laboratory, testing, and analysis services for materials, components, and technical systems. With precise analytics and modern testing technology, we create transparency, safety, and trust in everyday industrial life.

We are an internationally recognized testing institute for aerosol filtration with a wide range of tests – from pipette tip filters, cabin air and gas turbine filters to complete devices such as room air cleaners and vacuum cleaners. Particle separation performance and adsorption capacities, such as activated carbon filters, are tested for industries ranging from the automotive industry to cleanroom technology. Good to know: Fiatec has exclusive distribution rights for ISO 12103-1 test dusts and comparable products.

Since 1995, we have been the experts for sound material analysis and tested quality – with metallography, optical emission spectrometry, fracture assessments and comprehensive damage analyses all under one roof. This makes us one of the world's first accredited calibration laboratories for optical emission spectrometers. Precise spark spectrometry in particular enables exact elemental analyses for industries such as automotive, aviation, transport technology and medical technology. In this way, we create reliable results for industrial decision-making processes using state-of-the-art testing methods and a clear quality standard.