Certania

Industrial Inspection

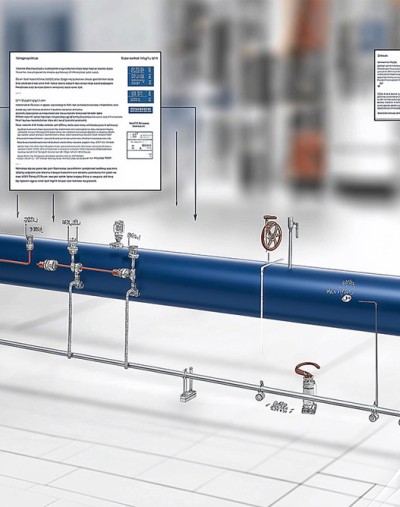

Our INDUSTRIAL INSPECTION segment offers a wide range of highly specialised inspection and analysis methods that ensure the safety, performance and service life of industrial systems. Key elements are non-destructive testing methods such as phased array and TOFD ultrasound, radiography, magnetic particle and penetrant testing as well as visual and geometric inspections. These methods make it possible to detect material defects, structural changes or signs of wear at an early stage – a critical factor in industries with high safety requirements such as energy, nuclear technology, manufacturing or mechanical engineering.

In addition, hardness measurements, localised heat treatments and automated testing processes are used to reliably evaluate both individual components and complex systems. In the field of noise and vibration technology, the causes of noise and vibration problems are analysed, while fluid mechanical investigations help to better understand system behaviour, efficiency and load.

The services cover all project phases: from planning support and assistance with commissioning through to monitoring and optimisation during operation. Workshops and specialised training programmes also strengthen the expertise of planners, operators and technical teams.

INDUSTRIAL INSPECTION thus creates a resilient basis for maximum operational safety, regulatory compliance and sustainable performance – wherever critical materials, complex systems and high quality requirements come together.

For a humanity in certainty

IndustrialInspection

For more than 45 years, the specialists at C.M.C. Sud have been among the international pioneers in non-destructive testing and safety-critical material inspections – from ultrasound and radiography technology to magnetic particle testing and heat treatment. With in-depth expertise in high-risk areas such as nuclear technology, energy and industrial manufacturing, we reliably ensure the integrity of safety-relevant components. We are also regularly involved in major international projects with state-of-the-art testing systems and in-depth expertise – and are regarded as a leading authority for precise, standard-compliant testing and inspection solutions.

When developing solutions for technical acoustics, sound insulation, system vibrations and flow technology, we benefit from half a century of experience. We support projects from the planning stage through to commissioning and optimization during operation. With our expertise, we support planners, manufacturers and operators in identifying the causes of noise and vibration problems and developing effective mitigation measures. Whether machine dynamics, immission control or pulsation studies: We combine analytical depth with practical recommendations to ensure reliable, safe and efficient systems.